News

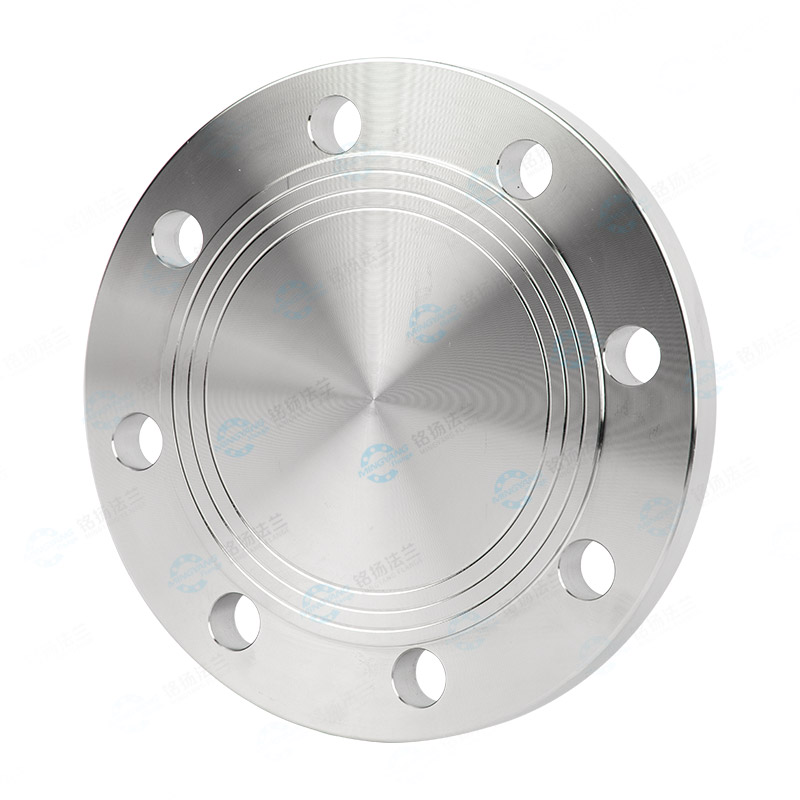

Flange covers, also known as blind plate flanges or blind plates, are flanges without holes in the middle, mainly used to seal pipe plugs. Its production materials are diverse, mainly including the following types:

I. Carbon Steel

Types: Including various models such as ASTM A105, 20#, Q235, 16Mn, etc.

Features: The carbon steel flange cover has strong compressive strength and good elasticity, and is suitable for pipeline systems under various pressure and temperature conditions.

Ii. Stainless Steel

Types: Mainly include models such as ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8, etc.

Features: The stainless steel flange cover has excellent corrosion resistance and is suitable for pipeline systems that need to resist chemical corrosion and high-temperature environments.

Iii. Alloy Steel

Types: Including various models such as ASTM A182 F1, F9, F11, F12, F22, F91, as well as materials such as 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, etc.

Features: The alloy steel flange cover combines high strength with excellent corrosion resistance, making it suitable for high-pressure, high-temperature and highly corrosive pipeline systems.

In addition to the above-mentioned main materials, the production of flange covers may also involve other special materials to meet the requirements of specific industries or applications. For instance, in industries such as petroleum and chemical engineering, it may be necessary to use special alloy materials with higher corrosion resistance and compressive strength.

In addition, the selection of production materials for flange covers is also influenced by the form of their sealing surfaces, connection methods, and usage environments. Therefore, when choosing the production materials for flange covers, multiple factors need to be comprehensively considered to ensure that they can meet the requirements of practical applications.